MILIN SALES CORPO.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to MILIN SALES CORPO.

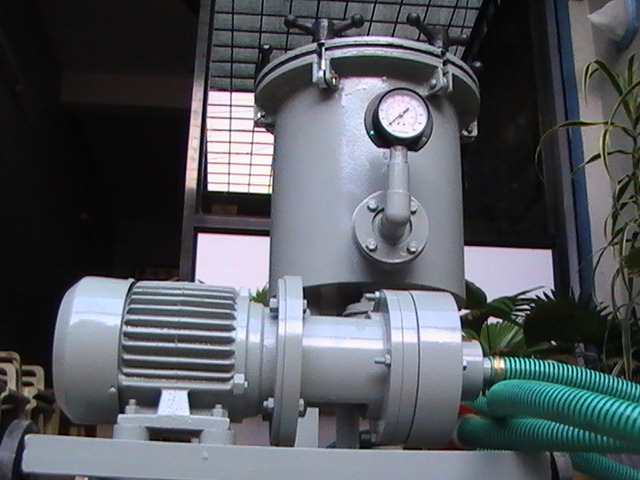

Filter P.P. Cartridge

Sartofine PP filter cartridges contain no pleated filter layers. For application purposes, they feature a 14 mm thick multilayer, consisting of 4 to 9 different filter zones. The number of zones depends on the type of cartridge. Each zone, made up of polypropylene filter layers is a homogeneous depth filter itself. The nominal retention rating of the respective filter zones becomes increasingly finer in the direction of filtration. Therefore Sartofine PP filters are ideally suited for all applications requirering exceptional high dirt holding capacities with added benefit of high total throughput. Applications: Whether in the bio-pharmaceutical or chemical industry, Sartofine PP filter cartridges are used wherever liquids with a wide range of particle sizes need to be prefiltered or clarified. You can choose from 7 different retention ratings (0.5 μm to 40 μm), depending on the size of the particles to be removed. This variety allows you to select the filter type which best suits your particular application. Efficiency: Particle removal by fractionated depth filtration ensures optimal use of the entire multilayer which results in a long service life of the filter. The filtration efficiency is enhanced by the filter cake that can be build up within the depths of each filter zone. This filter cake allows colloids to be retained in the finer filter zones. Mechanical Stability: Sartofine PP filter cartridges have been designed for daily routine use. Our special production method of wrapping the filter layers tightly around the supportive core of the cartridge provides high mechanical stability and eliminates the common problem of breakthrough right from the start. The thermally bonded exterior layer and our special welding technique for joining filter layers and end caps allow you to easily backflush the cartridges during cleaning at a pressure up to 3 bar (44 psi). Documentation: Sartofine PP cartridges are designed, developed and manufactured in accordance with a ISO 9001 certified Quality Management System. A Validation Guide is available for compliance with regulatory requirements.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.